Miniaturization trampled repairability and now governments, representing disgruntled consumers, are starting to drive manufacturers the other way.

While we await the European Commission’s “non-legislative” Circular Electronics Initiative, which will tell us just how far away from their definition of “circular” we, as an industry, are and undoubtedly result in additional regulation, I figured I’ll give you another example of circular thinking in the consumer electronics industry.

A fascinating company producing mainstream consumer electronic products is Fairphone, which began as a conflict minerals awareness campaign in 2010 and was incorporated as a manufacturer in 2013. They produce smartphones. While these are currently available only within the European Union (and Liechtenstein), the concept is somewhat similar to that of the Framework laptop I wrote about last month. Fairphone, as the name suggests, not only focuses on upgradability and repairability, but also on human rights in the supply chain.

A wide variety of spare parts and upgrades are available on the Fairphone website.

I can’t buy any spare parts for my increasingly obsolete LG V20 besides a new battery (and certainly the legitimacy at non-factory-authorized outlets of those labeled the same as the original LG battery is questionable): certainly not the camera module, speaker, or earpiece, like Fairphone sells. Well, actually I can buy a camera module, on eBay.

Various sellers make components available for a wide variety of products — some components are used and, they claim, refurbished (to whose specifications?); others are purported to be new and/or actual OEM items. I successfully repaired my wife’s Sony tablet with a USB charging port I bought on eBay a number of years ago — so miracles do happen. But is this how we want our products supported, either as a manufacturer or as a consumer? I think not: we want them designed to be repairable and for customer support to be intentional.

The repairability of Fairphone’s newest product, the Fairphone 4, rates a 9.3/10, according to the French repairability index I mentioned last May.

Design for repair — at the hands of professional repairers — and reuse is now baked-in to household dishwashers and refrigerators as well as TVs and computer monitors/displays in the European Union, due to regulatory requirements. With the accelerating “right to repair” movement and coming regulation in the EU and now in the USA, manufacturers across a very broad range of consumer and commercial electronics must change product architecture, design, and manufacturing goals and capabilities to enable repairability of products that, IMHO, should have been repairable all along.

Speaking of the USA, last month Apple announced that it will enable “self-service repair” of iPhone 12 and iPhone 13 products. This is big news and, as someone who long ago suffered through replacing my iPhone 3G’s cracked screen, quite welcome. In fact, I bet the Federal Trade Commission welcomes it as much or more. Last summer they “unanimously voted to ramp up law enforcement against repair restrictions that prevent small businesses, workers, consumers, and even government entities from fixing their own products.”

I’m not saying (and neither is the FTC) that Apple is among these manufacturers, but I vaguely recall having to deal with adhesive when replacing the 3G’s screen. Once I compromised the seal as part of the replacement process and did an admittedly poor job of adhering the new screen, dust eventually made its way behind the screen. Foreseeable problems like this will, of course, have to be addressed when defining requirements and the engineering approaches necessary for maintaining functionality and customer expectations while improving modularity and repairability.

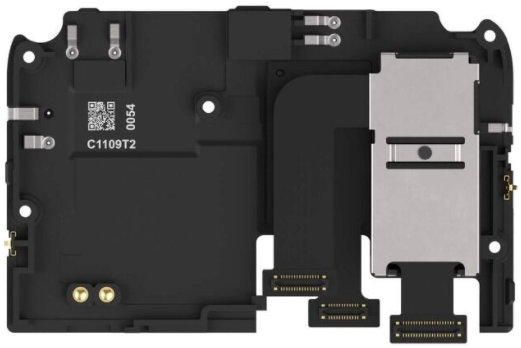

Modularity does have a downside: it means increasing the number of interconnections, and that means additional potential points of (mostly mechanical) failure. The image of the Fairphone 4 camera module in Figure 2 shows three connectors and several other contactors.

A camera system designed as part of the phone’s motherboard may not require all these additional interconnects. So reliability could take a hit. Manufacturers must consciously address mechanical robustness and reliability as a product goal because of this.

Miniaturization trampled repairability and now governments are starting to drive manufacturers the other way. Will consumers (and professional repairers) approve? If you can design modular, repairable, durable products while keeping the form factor in line with what consumers have come to expect, you may be on your way to winning the game. Fairphone and Framework seem to have done it; does your company name begin with F? Does it need to? Provide us examples of some other (consumer electronics) manufacturers that are meeting the requirement in the comments.

This article was originally published on EE Times.