Researchers are using extremely sophisticated techniques to see what’s happening inside batteries during charge and discharge cycles.

Batteries present a test and measurement dilemma and conundrum. On one side, the basic battery external parameters of terminal voltage, current, and temperature are fairly easy to measure. The next tier of assessments, such as assessing the state of charge, takes more time and effort but is certainly doable after the fact.

But seeing what’s going on inside the battery, especially while it is being actively charged or discharged—now that’s a real challenge. In that respect, a battery under evaluation is a genuine “black box.” Scientists, researchers, and engineers can speculate what is happening or happened—but it’s like working with a cadaver where it takes an autopsy—and the insight gained is often static due to the fact that the unit under test is now “dead.”

That doesn’t provide the amount and type of data and insight to support the efforts directed toward the better battery by battery vendors, universities, and other facilities. These researchers want to see what’s going on inside the battery in real time while it’s being used, a mode which the research community designates as in operando observations meaning “while in operation.” (This should not be confused with in vitro, meaning outside a living organism or in vivo, meaning inside a living animal or person.)

There has been some impressive progress in this area, but it’s been slow going and the test arrangements are not simple despite how they are described by the researchers. These are among the many efforts I have recently read about:

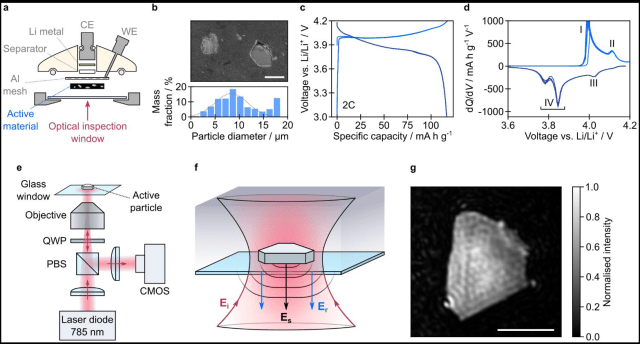

“Operando optical tracking of single-particle ion dynamics in batteries” (the published paper is behind a paywall, but fortunately there is an archived, unlocked copy here). This paper details work done at the University of Cambridge (UK) where a team has developed an optical microscopy technique called interferometric scattering microscopy to observe battery processes, Figure 1.

They were able to observe individual particles of lithium cobalt oxide (often referred to as LCO) charging and discharging by measuring the amount of scattered light, and also see the LCO going through a series of phase transitions in the charge-discharge cycle. The phase boundaries within the LCO particles move and change as lithium ions go in and out. The researchers found that the mechanism of the moving boundary is different depending on whether the battery is charging or discharging.

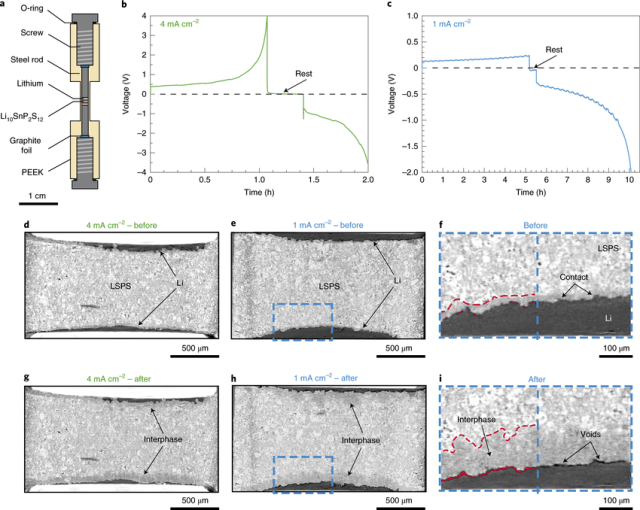

“Linking void and interphase evolution to electrochemistry in solid-state batteries using operando X-ray tomography” along with Supplementary Information; again, the primary paper is behind a paywall, but it’s also available here. A multi-institution team led by a group at Georgia Institute of Technology (Georgia Tech) and including Argonne National Laboratory has advanced a technique for looking inside the battery cell while it’s being charged and discharged, Figure 2.

This X-ray microtomography imaging is similar to a medical CAT scan. Their synchrotron X-ray “computed-microtomography” imaging revealed how the dynamic changes of electrode materials at lithium/solid-electrolyte interfaces determine the behavior of solid-state batteries. The researchers found that battery operation caused voids to form at the interface, creating a loss of contact that was the primary cause of failure in the cells.

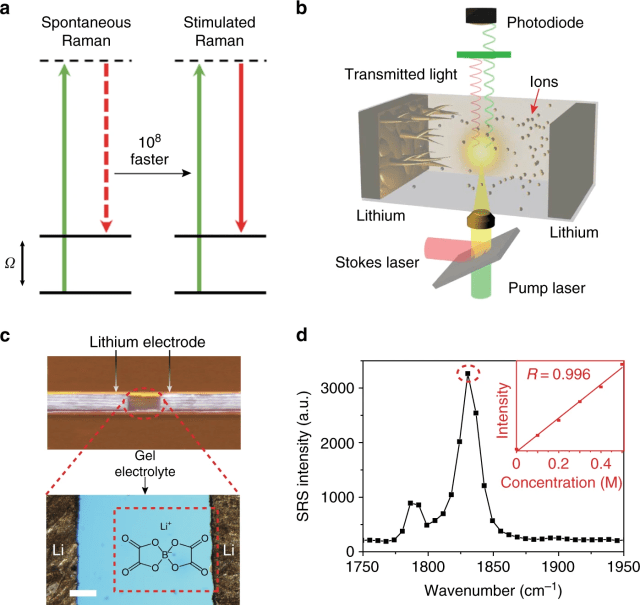

•“Operando and three-dimensional visualization of anion depletion and lithium growth by Stimulated Raman microscopy.” A team based at Columbia University (New York) is using Raman-scattering microscopy, an advanced spectroscopic electro-optical technique widely used in biomedical testing, chemical-process investigation, and materials science. In this stimulated scattering. a synchronized pump-laser beam and a swept-wavelength Stokes laser beam are combined, and the combination interacts with the sample, which causes it to generate a coherent optical response, Figure 3.

By measuring the vibrational resonances as the impinging beam is swept, the detailed “fingerprints” of the target molecules are revealed. The results revealed a multi-stage positive-feedback mechanism resulting in uneven growth of ion concentration. Those regions that had a higher concentration underwent a higher growth rate, which in turn led to further increase in concentration and accelerated growth rate of the undesirable dendrite crystals.

“In-operando high-speed tomography of lithium-ion batteries during thermal runaway,” describes how a team at University College London (UK) developed a complex set-up to perform an internal computerized axial tomography (CAT) scan on lithium batteries in real time. The objective was to get detailed insight into well-known unfortunate aspects of these batteries, fortunately occurring only under some unique circumstances or due to manufacturing defects: their tendency to overheat and explode/catch fire, generally called thermal runaway.Each of these techniques provides us with more of the insight needed for better understanding of live-action battery electrochemical processes. But they are all complicated to set up and evaluate, and certainly don’t have the convenience of our portable or benchtop electronic instrumentation. Instead, they are a sophisticated blend of electronic, optical, and deep-physics systems and arrangements.

Battery chemistry will not give up its secrets easily, but that is not stopping us from trying. Will there be a single or series of breakthroughs? Or will progress be made by relentless, slow, steady progress. We learn from history that scientific, engineering, and manufacturing progress is due to a combination of both. The real issue is the relative weighting between the two modes for developing the innovation and taking it to maturity and application. As the saying goes, “only time will tell.”

This article was originally published on EE Times.

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple EE Times sites and as both Executive Editor and Analog Editor at EDN. At Analog Devices, he was in marketing communications; as a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these. Prior to the marcom role at Analog, Bill was Associate Editor of its respected technical journal, and also worked in its product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls. He has a BSEE from Columbia University and an MSEE from the University of Massachusetts, is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.